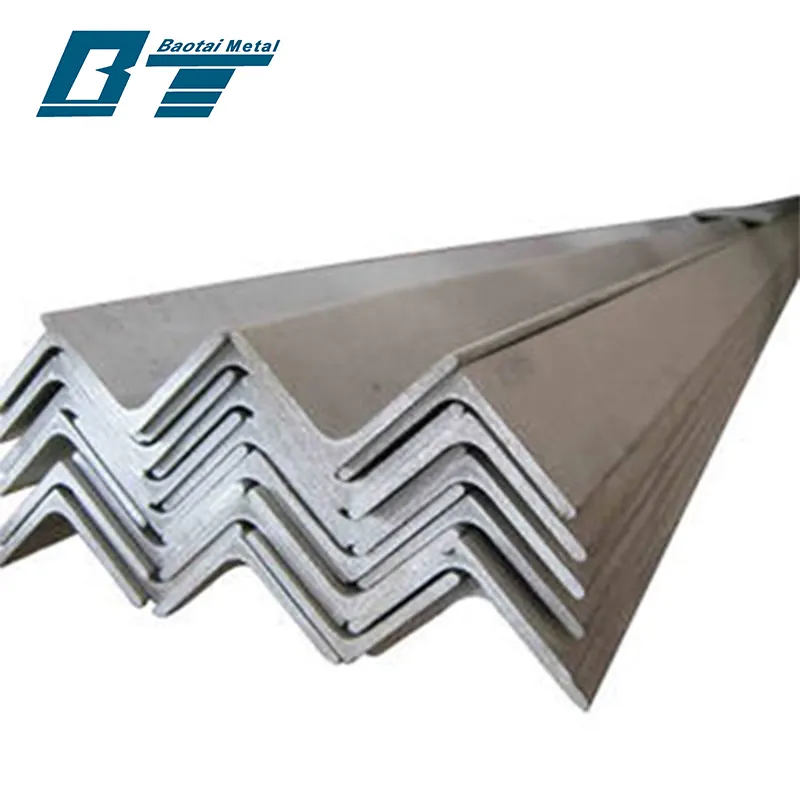

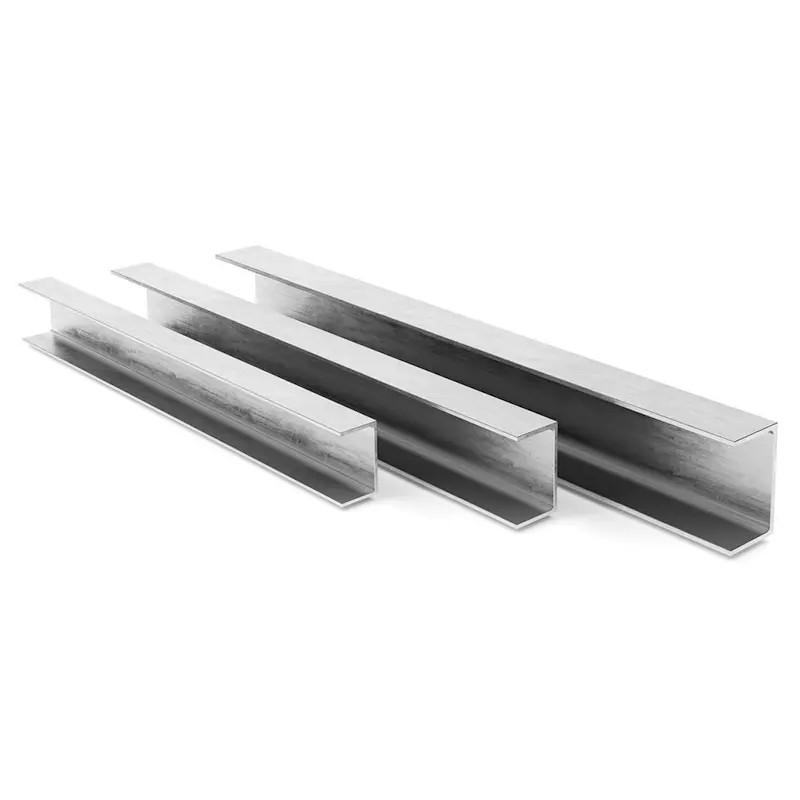

Bariga badbaadada dhammaan waa ugu yar ee ku jira in lagu talagalay oo ka mid ah carruurka badbaadada, kuwaas oo la isku jiro geedka iyo xaaladooda carruurka (low carbon) ama carruurka dheer (medium carbon), waxaa lagu deggan doontaan qof qabtaanka ee 400-700 MPa haddii uu ku jirin macluumaadka dibinta. Carruurka low carbon (ASTM A36, EN S235) waa laf ah oo ku jiraan koonfurka caafimaadka hore haddii uu ku jirin weldability iyo formability, markaasaa carruurka medium carbon (ASTM A108) waa laf ah oo ku jiraan carruurka dheer ee ku jirin hardness leh koonfurka mashinaha. Proceska hot rolled waa la isku jireen production, si toos ah carruurka cold rolled waa la jirin tolerances dheeraad ah leh components ee ku jiran precision. Xaqiijinta surface protection methods waxaa lagu deggan doontaan hot dip galvanizing (80–275 g/m² zinc coating), electroplating, ama powder coating, carruurka uncoated waa laf ah oo ku jiraan interiors ee ku jiran paint. Bariga badbaadada carruurka waa laf ah ee ku jiraan automotive frames, agricultural equipment, iyo storage racking, haddii uu ku jirin L shape ayaa lagu talagalay in ay uga soo baxaan load transfer. Waxaad u baahan doontaan fabrication considerations waxaa lagu talagalay in aad ugu joojin welding electrodes carruurka (misheen E6013 carruurka low carbon, E7018 carruurka medium carbon) iyo ku saabsan anti spatter compounds si aad uga soo jeedo surface quality. Haddii recycling initiatives ku jirin, carruurka badbaadada carruurka made from scrap steel carruurka carruurka carruurka alloy content ayuu ku jirin momentum, bal eeg carruurka performance environmental sustainability.