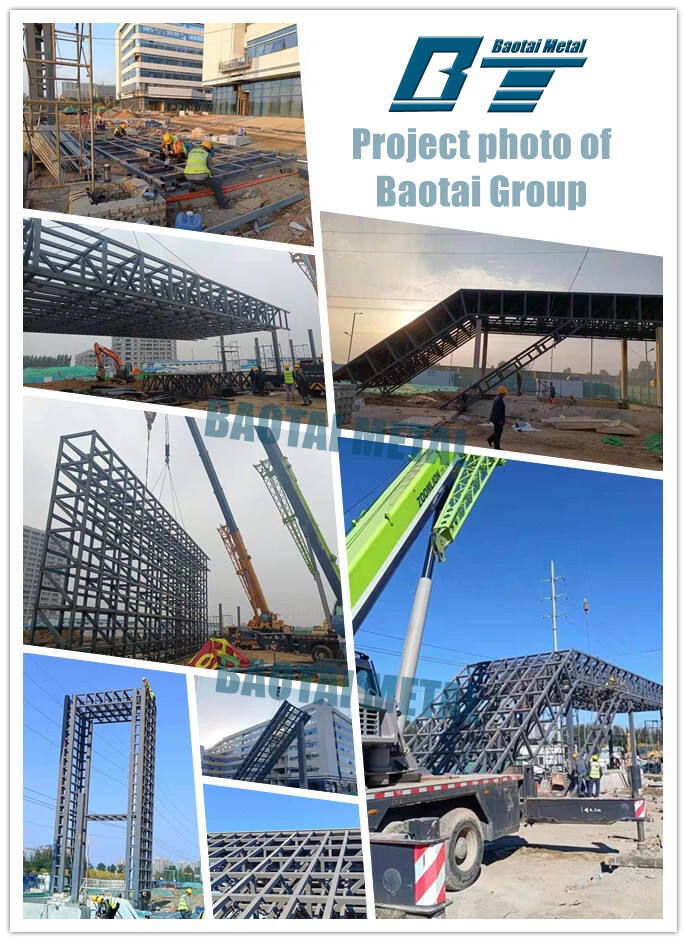

Construction Case 2

In order to ease the traffic pressure on crowded roads in the downtown business district of Thailand and improve pedestrian safety and traffic efficiency, our company adopted all-steel structure design and participated in the construction of a modern overpass with a span of 42 meters. The project uses steel as the core material, giving full play to its advantages of lightweight, high strength, and fast construction. The main construction was completed in only 90 days, becoming a landmark convenience facility in the region.

The core advantages of steel are reflected in this project

1. High strength and lightweight to achieve large-span design

Material selection: The main beam is made of Q345B low-alloy high-strength steel with a yield strength of 345MPa, which is 60% lighter than traditional concrete structures. It only needs 4 steel columns for support, reducing the occupation of ground space by bridge piers.

Structural optimization: The box-section steel beam is matched with a truss bridge body, which ensures the bearing capacity while achieving visual transparency of the bridge body, perfectly meeting the aesthetic needs of the city.

2. Factory prefabrication + on-site assembly, shortening the construction period by 50%

All steel components are prefabricated in a standardized manner in the factory (accuracy is controlled within ±2mm), and assembled by high-strength bolt connection and welding technology after transportation to the site, avoiding wet work on site, and construction can still be carried out on rainy days.

Compared with the traditional solution: the concrete cast-in-place requires a 28-day maintenance cycle, and the steel structure only takes 15 days to complete the main hoisting, greatly reducing the impact on surrounding traffic.

3. Outstanding durability and environmental protection

The surface adopts the "hot-dip galvanizing + fluorocarbon spraying" dual anti-corrosion process, with a weather resistance of more than 30 years, adapting to urban acid rain and salt spray environments.

Steel is 100% recyclable, and the material recovery value after demolition is 80%, and the carbon emissions over the entire life cycle are 40% lower than that of concrete.

4. Excellent seismic performance

The ductility of steel (elongation>21%) effectively absorbs seismic energy. Combined with the shock-absorbing bearing design, the seismic fortification intensity reaches 8, and it was rated as a "demonstration seismic project" by the local Housing and Construction Bureau.

Technological innovation highlights

BIM full-process application: BIM modeling from design to construction, solving pipeline collision problems in advance, and the qualified rate of steel component installation is 99.6%.

Intelligent monitoring system: Strain sensors are embedded in the bridge body to monitor stress and vibration data in real time to ensure long-term safety.