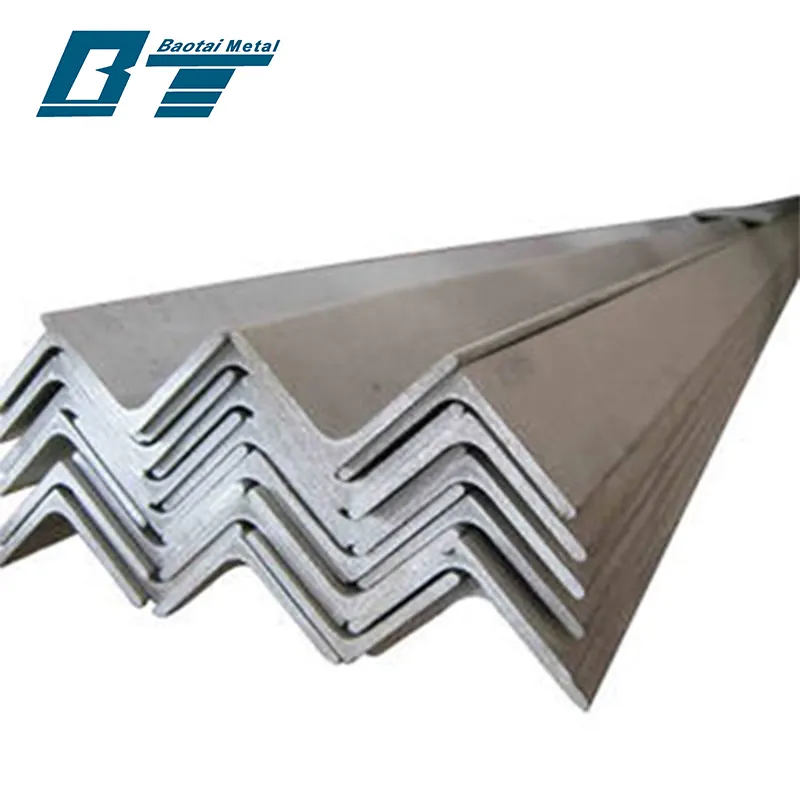

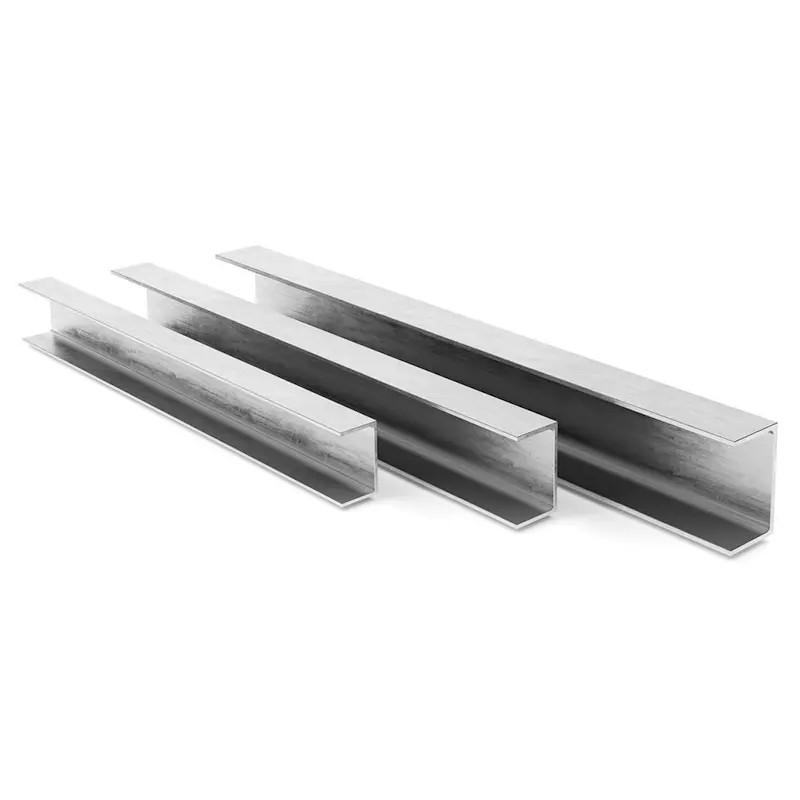

Angle bar manufacturers operate integrated facilities to produce high quality structural sections, combining metallurgical expertise with advanced manufacturing technologies. The production process begins with raw material selection—scrap steel or iron ore melted in electric arc furnaces or basic oxygen furnaces—followed by continuous casting into billets. For hot rolling, billets are reheated and passed through rolling mills with custom dies to form the angle shape, while cold rolling involves further processing at room temperature for precision. Heat treatment furnaces normalize or temper the bars to optimize mechanical properties, with automated systems controlling temperature and cooling rates. Quality control labs perform chemical analysis, tensile testing, and impact tests to ensure compliance with ASTM, EN, or JIS standards. Modern manufacturers leverage digital twins and predictive maintenance to enhance production efficiency, while robotic systems handle material handling and automated cutting. Customization services allow production of non standard angles, special alloys (e.g., weathering steel), or coated products (zinc aluminum alloys). Research and development focuses on reducing carbon footprints through electric arc furnace recycling, low energy rolling processes, and eco friendly coatings, aligning with global sustainability goals.